)

Jungheinrich expands Keller & Kalmbach warehouse

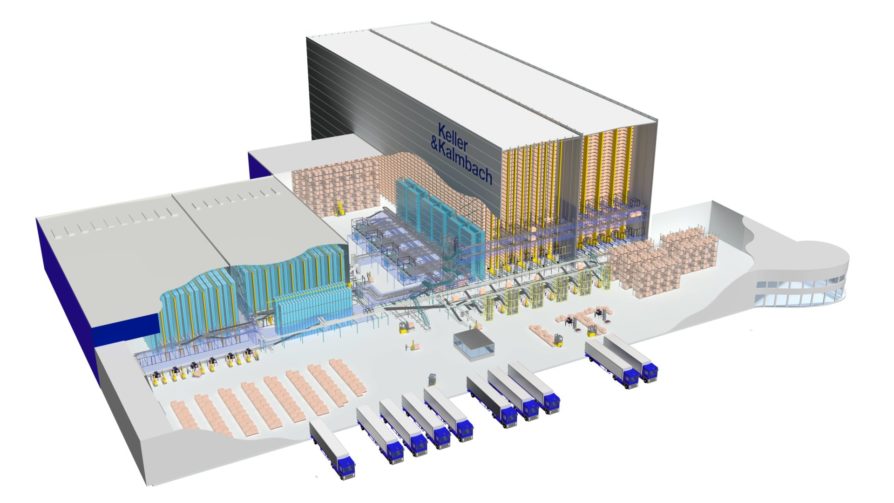

Keller & Kalmbach, a specialist in fasteners, fastening technology and intelligent C-parts management, is expanding the capacity of its central warehouse and distribution centre in Hilpoltstein, Bavaria, for the second time. Jungheinrich has been commissioned to build four new aisles in the carton warehouse there by the end of 2023, in addition to the six existing aisles of the miniload. The partnership goes back a long way: even in the first construction phase of the central warehouse, which went into operation in 2009 and marked Keller & Kalmbach’s entry into automated systems, the family-owned company with over 140 years of history relied on Jungheinrich. Due to the success of the collaboration, Jungheinrich had already been commissioned with the first expansion stage in 2016. Now, the order for the second has followed.

“Over all these years, we have continuously worked together on optimising the warehouse and already doubled the capacity with the first expansion in 2016,” reports Robert Schad, senior project manager ASRS at Jungheinrich. “At that time, we already planned the next expansion, which is now being realised.” This is because Keller & Kalmbach had calculated strong further growth at the time of the first expansion six years ago, which has since occurred and made additional warehouse capacity in the miniload necessary: with a 20% increase in turnover to 350 million euros, the full-service provider had a record 900 employees in 2021, and Keller & Kalmbach also took over several companies last year. All of this made the expansion necessary.

Jungheinrich is creating a total of 79,968 additional carton storage spaces (+25%) through the expansion on the 44,000sqm site in Hilpoltstein where, in addition to pallet and carton storage, two tray storage systems ensure a smooth flow of materials. Thanks to suitably designed picking workstations, pallets and cartons can be processed in combination and precise customer requirements implemented. Keller & Kalmbach supplies customers from the automotive and commercial vehicle industry, mechanical and plant engineering, railway, agricultural and construction machinery industries.

Jungheinrich is supplying four stacker cranes and the carton conveyor technology for the current warehouse expansion, each including control and visualisation. The Hamburg-based company’s scope of supply also includes the steel racking structure (55 x 12.5 x 14.3m), project management and the Jungheinrich WMS. As the warehouse was designed with foresight in 2016, the space for the four new aisles, the system for the conveyor technology in the pre-zone and corresponding constructions are already available in the current expansion. The new aisles will be connected to the existing conveyor technology and warehouse management software.

In fact, one of the most comprehensive WMSs from Jungheinrich is already in use in Hilpoltstein. Moreover, as a trendsetter, Keller & Kalmbach recognised the advantages of automation, such as high efficiency, precision and scalability, early on. “Not only has Keller & Kalmbach grown with us over the years, but we have grown with them,” says Schad, alluding to the fact that numerous Jungheinrich customers and prospective customers have visited the central warehouse south of Nuremberg, making it a successful reference.

“We have a long-standing and well-developed partnership with Jungheinrich that is characterised by transparency and a high level of mutual trust. This is enormously important for us and we are very satisfied,” says Sebastian Malicki from Keller & Kalmbach’s business innovation team. “We are pleased to have a good partner on board with Jungheinrich in these challenging times. It’s almost like being in a good marriage for 15 years.” This long marriage includes a service contract with Jungheinrich, which now also applies to the new aisles. And the next joint project is already on the horizon: after the carton warehouse, capacity in the pallet warehouse is also to be expanded.