)

New conductive material for conductor rails transmits high currents during standstill

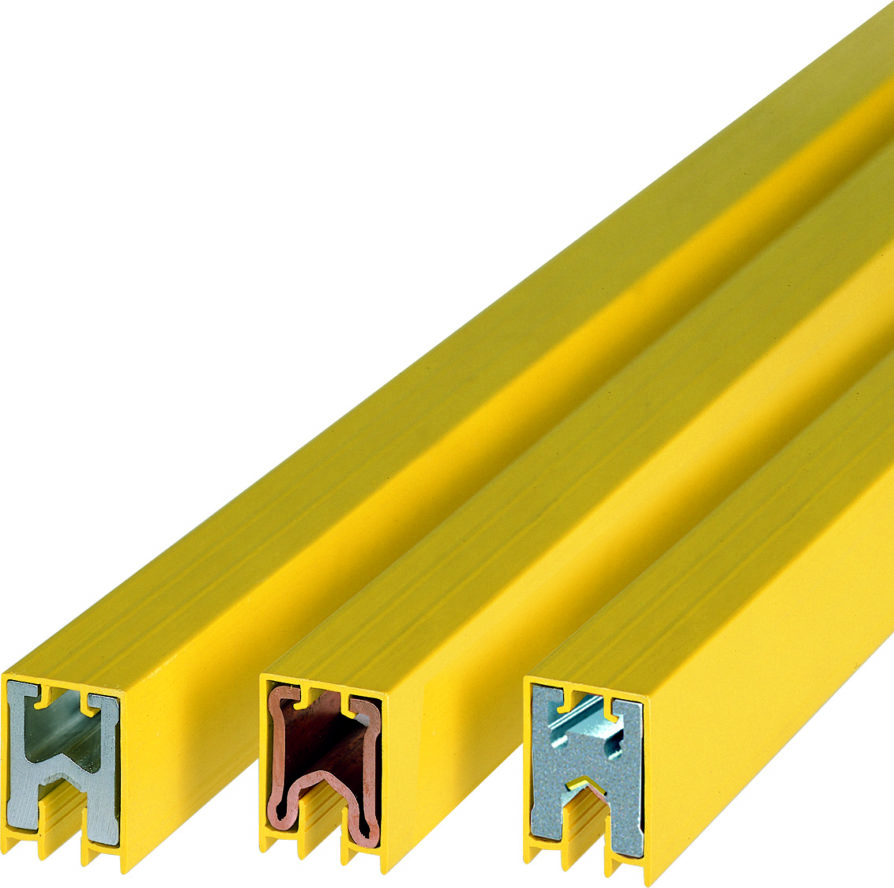

Conductix-Wampfler, has launched a new conductor rail type CopperECO. CopperECO was developed as an economical, efficient solution to a challenge that equipment manufacturers and operators are constantly facing: the transmission of high currents to the consumer while the mobile unit is not moving, ie is at a standstill, as is the case with load handling devices in lifting operations without simultaneous longitudinal travel of the crane.

Up to now, the only choice of conductive material has been between premium copper with the best conductivity and aluminum-stainless steel variants, which are at lower cost but tend to heat up locally when at a standstill due to the material properties. In order to ensure the safe operation of the equipment even in critical applications, often complex multiple current collector combinations with high space requirements had to be installed.

With CopperECO, Conductix-Wampfler has designed a price-performance alternative between copper and aluminium-stainless steel. This new rail type offers significantly improved conductivity compared to aluminium-stainless steel and thus allows the safe transmission of high currents even during standstill operation. CopperECO is also suitable for demanding outdoor environmental conditions, including seaports.

CopperECO rail types are available for the Single PowerLine 0812 and 0813 conductor rail series and are particularly suitable for the reliable power supply to container and overhead cranes, AS/RS, cable propelled people movers or amusement rides.